Welcome to Pecanhood Integrity.

Your Asset Integrity Management Partner

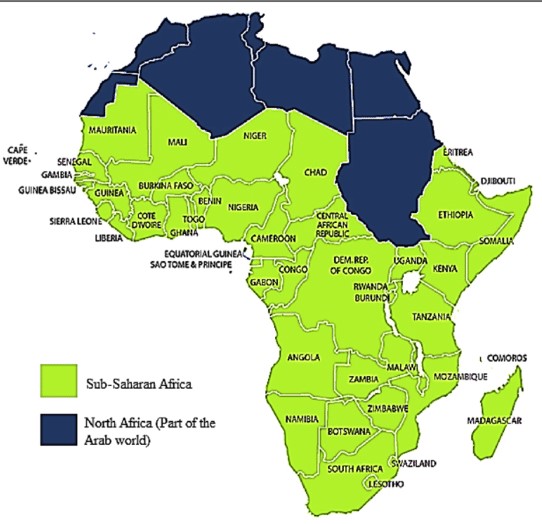

Established in 2015 to serve and support the Oil and Gas industry in Southern Africa.

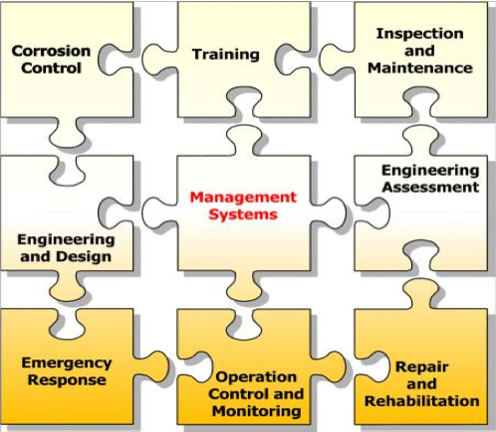

Pecanhood Integrity provides specialized Engineering support and Project Management services to the upstream, midstream and downstream pipeline, Petrochemical, Power Generation, Chemical storage, Bulk water systems and Airports industries.

We have a highly engaged multi-disciplinary team, passionate about addressing the challenges of Pressure Equipment, Product Storage, Process Safety Management and Project Management. We are 'Your Asset Integrity Management Partner'.

Our value proposition: We offer data driven specialist support services, providing advanced Engineering solutions on pressure equipment and storage facilities to reach operations excellence and statutory compliance. Ultimately our goal is to prevent unnecessary downtime, consequential environmental damage, saving costs and preserving human lives.

Key Services + Products :

Our Core Services

Engineering Critical Assessment

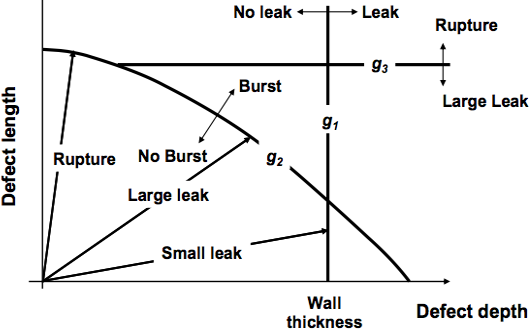

We have expertise to assess anomalies from In-line inspection (ILI) or any NDT results, and determine the fitness for Service, applying Fracture mechanics from Level 1 up to Level 2. Corrosion damage such as pitting or Microbial Induced Corrosion, Geometric defects such as dents and Crack-like defects are all assessed using either API 579 methodologies and/or DNV and/or PRCI recommended practice.

Our Engineering team is ready to partner with you on any engineering assessment challenge. For more information refer to the brochure below:

Geo-Hazard assessment and Integrity Incident management

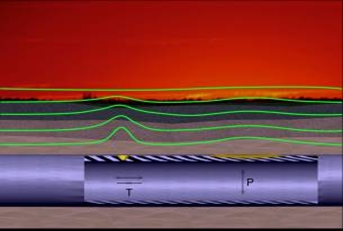

Injurious damage on pipelines such as stray current corrosion causing deep localized pitting and geo-hazard damage causing pipe buckling are all regarded as Integrity incidents. They all require a pragmatic approach to determine the direct cause and root causes.

Corrosion Growth Rate Assessment

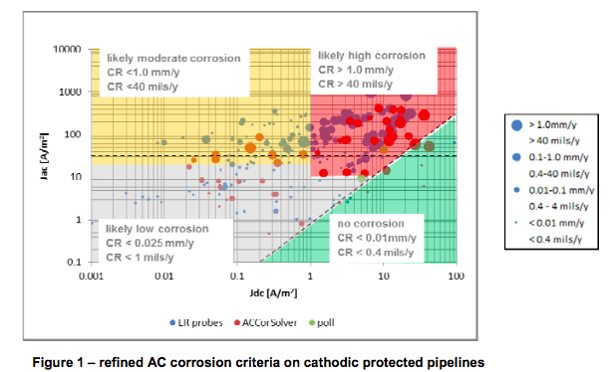

We are well aware of Global trends with regards to AC/DC Stray current corrosion. We make use of Global resources such as PRCI to determine credible Corrosion Growth Assessment (CGR) based on the corrosivity, presence of AC stray currents, inspection/anomaly data and probability theory.

We have knowledge and tools for modelling data statistically using cutting edge software i.e. Mathematica software.

We also offer support with regards to AC/DC stray current investigations and mitigation.

Our Engineering team is ready to partner with you in solving your Corrosion challenges. Image Courtesy of PRCI

Inspection management

Our experience in pipeline operations and inspection of piggable and unpiggable pipelines is extensive. We offer sound knowledge and support in ILI, MTM, SCT and ECDA projects.

On ILI/MTM/SCT/ECDA projects, we provide critical services not limited to preparations, training of staff, operating manuals and procedures, coordination between service provider and Operational teams and overall execution of inspection operations.

Our Engineering team is ready to add value to your next Inspection project.

Environmental Solutions

Greenhouse Gases (GHG) & Carbon Tax compliance

We are well aware of the International Panel on Climate Change (IPCC) codes and the associated formulae for determining Carbon Dioxide and Methane for various industries.

We provide insights and solutions to ensure compliance to the South African NEMA Air Quality Act No. 39 of 2004, relating to reporting of GHG's on SAGERS system.

We also provide insights and solutions to ensure compliance to the South African Revenue Services (SARS) Carbon Tax Act 15 of 2019 for GHG's emissions.

Our team is ready to tackle your compliance challenge on GHG emissions.

Project Management Services

We are well experienced in Project Management services in the Oil and Gas, Airport, Chemical storage and Pipeline industries. We also support our International partners in executing special projects. We provide Project Management, Support, Planning, Engineering, Cost engineering, Process Safety and Risk expertise. Our processes are streamlined for efficiency and diligence.

Get in touch with us for any Project Management related assignment.

Management Consulting

Even though our roots are in Africa, we offer global, impartial and structured thinking on any special assignment around Oil and Gas related Business Management Consulting. Our team's proficiency and work ethic is an assurance to our workmanship.

Technical Training

We offer Industry sought training relating to Pipeline Integrity management.

Introduction to Safe Pigging Operation

Pipeline Isolation Technology - STATSGroup

Composite Repair Technology - 3XEngineering

Pecanhood Integrity and 3XEngineering from Monaco have agreed on a strategic partnership, to grow the 3XEngineering product brand in the South African market.